SOLAR PV MODULE MANUFACTURING PROCESS

11/10/2021

Solar PV (photovoltaic) modules are made up of multiple solar cells that convert sunlight into electricity. The manufacturing process for solar PV modules generally consists of the following steps:

1.Silicon Ingot Production: The first step in solar PV module production is the production of silicon ingots. The ingots are made by melting high-purity silicon and then cooling it slowly to form a solid block.

2.Silicon Wafer Production: The silicon ingots are sliced into thin wafers using a wire saw. The wafers are then cleaned and polished to remove any impurities or defects.

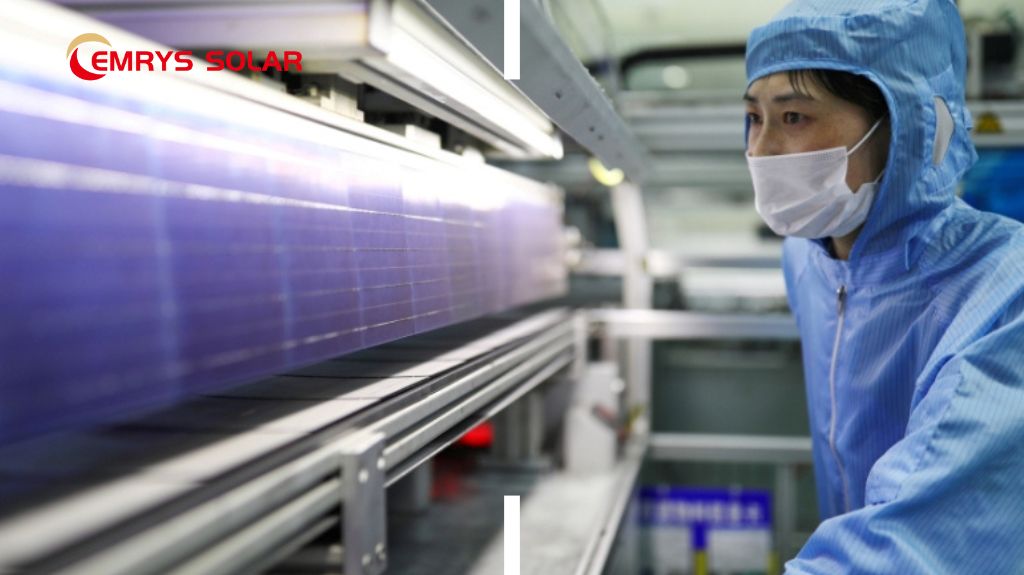

3.Cell Production: The silicon wafers are processed into solar cells. This involves etching a grid of tiny lines on the surface of the wafer to create a series of individual squares or rectangles. The cells are then coated with a layer of antireflective material to improve efficiency.

4.Module Assembly: The solar cells are assembled into modules, which are the building blocks of a solar panel. The cells are connected to each other using metal conductors, and the module is encapsulated in a layer of glass or plastic to protect it from the elements.

5.Testing: The finished modules are tested to ensure that they meet industry standards for efficiency and durability.

6.Packaging and Shipping: The final step in the manufacturing process is packaging and shipping the finished modules to customers.

Overall, the solar PV module manufacturing process is a complex and precise process that requires specialized equipment and skilled workers.